1.Project background

With the upgrading of the animal husbandry industry and the improvement of food safety requirements, traditional free-range farming methods have gradually been replaced by efficient, environmentally friendly and standardized cage facilities. Based on the introduction of cage breeding technology, the modern broiler breeding project in a certain region aims to create a “quality project” to achieve the goals of high production capacity, high quality and high efficiency, and set an industry benchmark.

2.Design concept

The project adheres to the design concept of “green and environmental protection, intelligent and efficient, scientific management, and standardization” and focuses on the organic combination of the breeding environment and animal welfare. It is mainly reflected in the following aspects:

Environmental protection and energy conservation: adopt circulating water systems and efficient ventilation equipment to reduce energy consumption and waste emissions.

Intelligent control: introduce automatic feeding and intelligent monitoring systems to realize dynamic regulation of environmental parameters.

Scientific layout: reasonably divide production areas, living areas and environmental protection treatment areas, and optimize space utilization.

Standardized management: Establish a complete operating procedures and quality traceability system to ensure product quality.

3.Construction technology

During the construction process, we pay attention to technical details and quality control, mainly including:

Foundation construction: A solid foundation ensures the stability of the cage, and various pipelines are pre-buried to facilitate subsequent equipment installation.

Cage structure: stainless steel or high-strength steel is corrosion-resistant and easy to clean, ensuring a long service life.

Environmental control system: Install automatic temperature control and humidity control equipment, as well as efficient filtration and ventilation systems to ensure the stability of the environment.

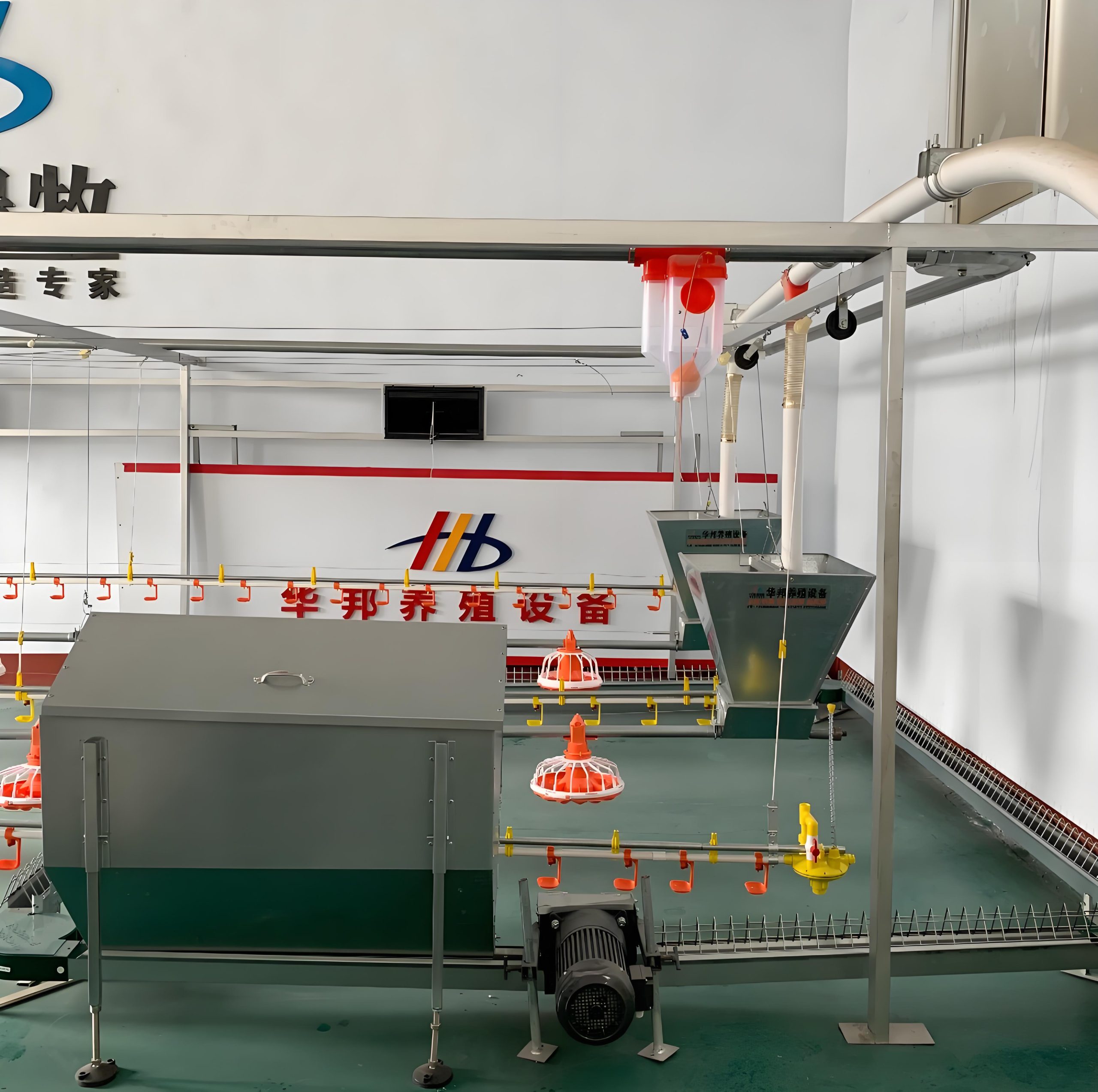

Installation of automation equipment: including feeder, drinking water system, feces cleaning equipment and monitoring system to improve operating efficiency.

4.Operations and Management

Scientific feeding: reasonably formulate feed ratios and feeding plans based on the healthy growth cycle of animals.

Environmental monitoring: Real-time monitoring of temperature, humidity, ammonia concentration and other parameters, and timely adjustments.

Disease prevention and control: Establish an early warning mechanism for epidemics, conduct regular health checks and vaccination.

Data management: Use information platform to collect, analyze and optimize the management of breeding data.

5.Project effectiveness

Through the implementation of the cage and quality project, significant results have been achieved:

Yield increase: The production capacity per unit area is increased by more than 30% compared with the traditional method.

Product quality: tender meat, bright color, and highly recognized by the market.

Economic benefits: The investment return period is shortened and profits are significantly increased.

Environmental protection effect: waste recycling, reduces the impact on the environment, and meets the requirements of sustainable development.